|

List Price

|

Fit and Finish

_________________________ |

Rough Water Speed

|

Smooth Water Speed

|

Accel using "Buttmeter"

....................................

|

Rough Water "Attitude"

....................................

|

Smooth Water "Attitude"

........................................ |

| Stock |

$0-$15

|

Very good for a cast part. Standard Variances from machine to machine.

Part lines up, first time, every time. Transition from shoe to plate is

very flat and sealed. |

60

|

70

|

The standard. It tends to push a lot of water before popping up.

|

GLUED to the water. No bounce, no misdirection

or trackin issues. No reason to expect a getoff at any time. Turns are

predictable, and smooth. Pump unloading is best in class. |

Leaves you wanting more speed. Plate is even MORE glued to the water.

The best plate to judge detonation limits. Turning is downright boring

and predictable. How hard can you hold on!? |

| R&D/Riva |

$170

|

Variences from Plate to Plate. Grinding is sometimes required to clear

pumps and other stuff. Both companies very good about replacing manuf defects

on part. Plate lines up, first time, every time, however, watch for flatness

and centering of components. |

55

|

74

|

Better than stock. Hull "leaps" forward,

and helps get it out of water more. Can induce "off the line" porpoising.

|

Not designed for rough water. Plate can

easily come unhooked in rough water. If spaced down with washers, rough

water speed decreases even further due to side-plate scrubbing. Turns can

cause a chine hop and "digging" if not controlled by rider. Pump unloading

is TERRIBLE, and is probably a cause for crank failure. |

My assumption is that this plate was design to

win smooth water grudge races. It is fast

on glass, and quick out of the hole to boot. This is the "River King" of

rideplates. Turning is pretty quick and tends

to "whip" around on you if possible. |

| ShredMaster |

$450

|

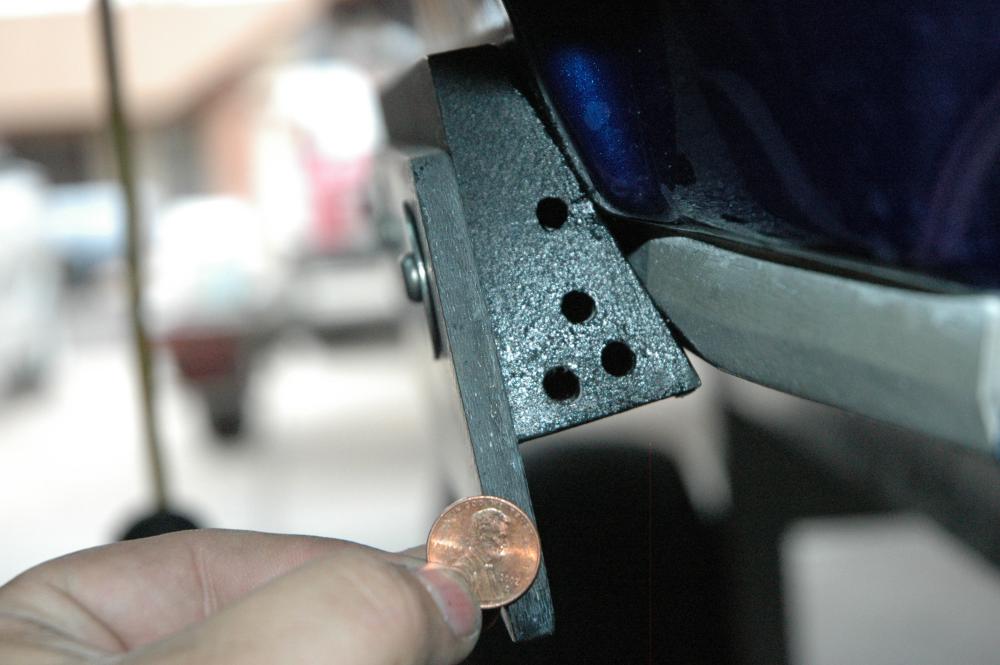

Grinding seems to be the word of the day.

Speedo 4-bolts did not line up properly on this plate. Holes had been drilled

out by owner to fit his ski. It BARELY FIT my holes. I HOPE I did not damage

my stock rideplate inserts. Posted letters from ShredMaster indicate any

problems you find are only YOUR problem, and nobody else has them. It is

a very "pretty" plate, and has a cool look. |

62 |

69 |

Not much different than stock. Possibly pushes a tad more water, but

seems to pop out about the same. Good hookup keeps the ski from hopping

in just about any condition. |

Absolutely, a rough water plate. The rear "rudder"

on this plate makes for a very planted attitude. This plate could load

your engine in mild rough water. The pump tends to stay full as well. Not

a bad plate for closed course or ocean riding. |

This plate does not work for smooth water. It is way too planted and

leaves you wanting more and more. You will sieze your motor trying to lean

for more speed...DON'T. Richen the motor. It's actually lugging your engine.

The plate turns very nicely in both rough and smooth...better hold on. |

Pro-Tec-

sorry, no pic. |

$170

|

Plate lines up, first time, every time. Grinding not found to be needed.

Pro-tec has always been an up-front company. If the part is not correct,

they will make it correct. Good folks. |

56

|

72

|

Not much different than stock. Not bad, not good.

|

A nice comprimise between rough water ability

and smooth water ride. I like this plate with 2-up riding. Still

this plate can induce bounce in rougher conditions. Not a good "race plate",

but very good for rec riders, lake riders. Pump unloading is not severe,

but is noticeably worse than stock. |

Very stable and predictable. You find yourself pulling back on the

bars, or leaning out your carbs. Turning does not seem to be a problem.

No strange tendencies. |

-Stock

blades are already "burn victims"... Yamaha, what were you thinking? Another

shot of the cavitation marks... Less than 5 hours on ski.

-Stock

blades are already "burn victims"... Yamaha, what were you thinking? Another

shot of the cavitation marks... Less than 5 hours on ski.

-Shaft

tool to hold driveshaft while doing prop work.

-Shaft

tool to hold driveshaft while doing prop work.

-Using

a pipe wrench to hold the shaft tool, and an adjustable (large) to tighten

the new prop. Clockwise, loosen.

-Using

a pipe wrench to hold the shaft tool, and an adjustable (large) to tighten

the new prop. Clockwise, loosen.

-Top

down view of the pump, shaft, and new 13/19.

-Top

down view of the pump, shaft, and new 13/19.

.

.  -Final

installation of the Pro-Cone onto the Solas 13/19.

-Final

installation of the Pro-Cone onto the Solas 13/19.

-All

the shiny new parts...

-All

the shiny new parts...

-Fresh

outta Da box!

-Fresh

outta Da box!

-This

is what the Solas looks like installed WITH the stock washer in place.

Note the large gap between pump/prop.

-This

is what the Solas looks like installed WITH the stock washer in place.

Note the large gap between pump/prop.

-Removal

of the stock washer for a tighter fit of pump/prop.

-Removal

of the stock washer for a tighter fit of pump/prop.

-The

stock washer removed.

-The

stock washer removed.

.

.  -Ah,

the finished product. On to the water.

-Ah,

the finished product. On to the water.